Disc Mill

Insmart Disc Mill

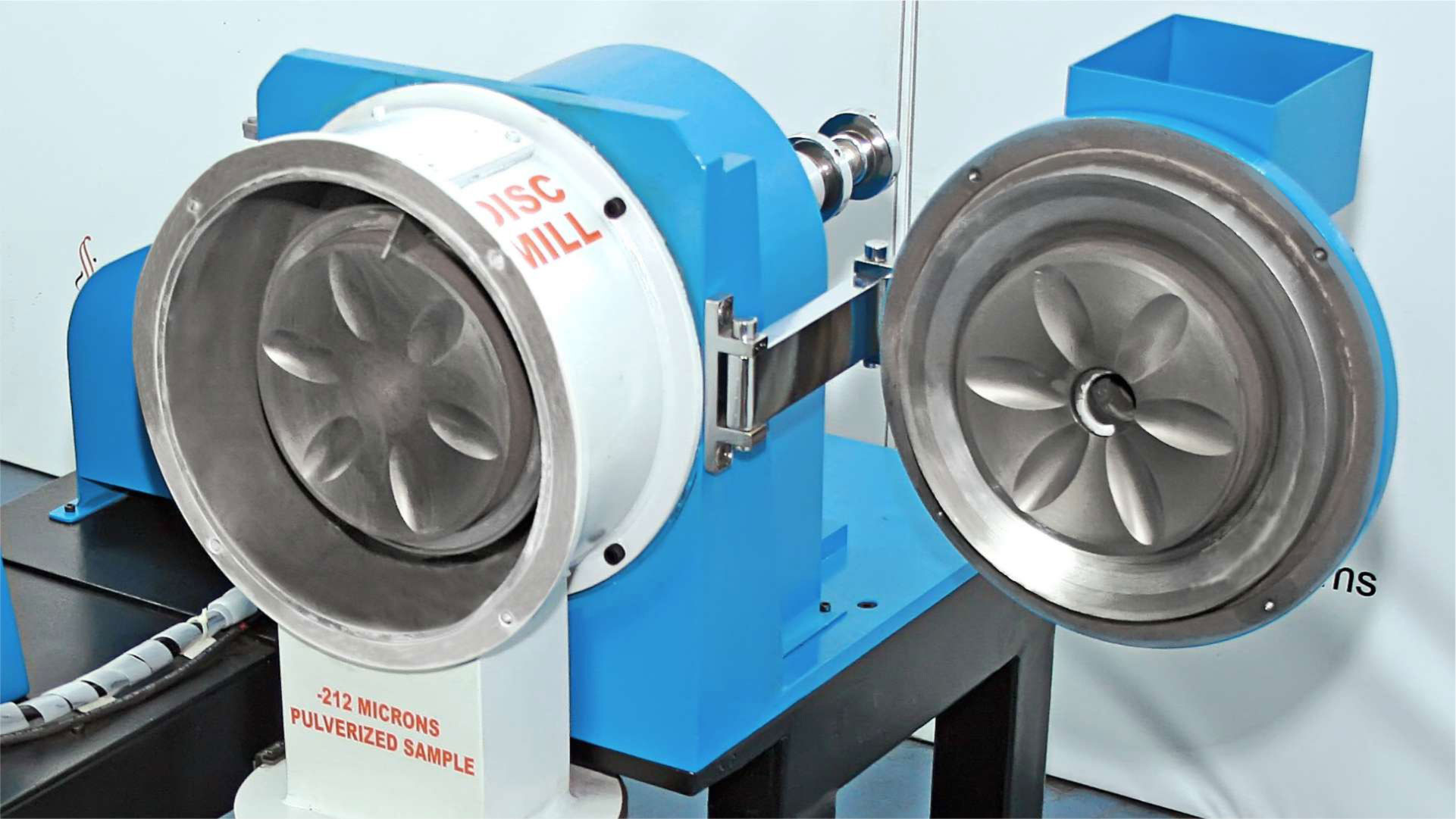

INSMART’s disc mill is extensively used for pulverizing of coal and coke samples. Crushing is done by friction and shearing action between a fixed and a rotating disc.

Special Features:

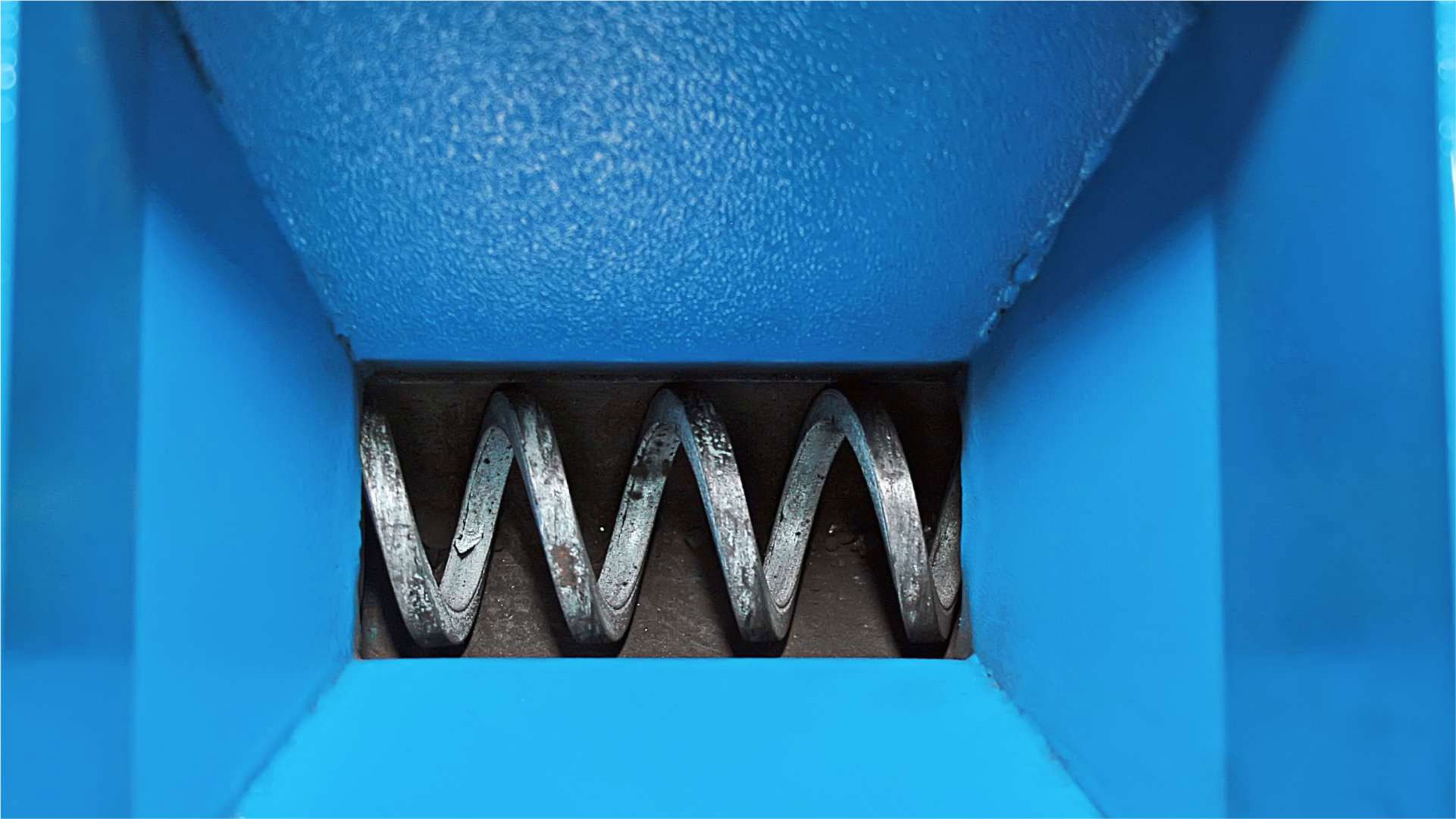

A highly innovative feeding system through a screw feeder for regulated feeding of the material in grinding zone

A positive air pressure system to evacuate the ground material into collection bin eliminating manual cleaning of the grinding zone after each operation.

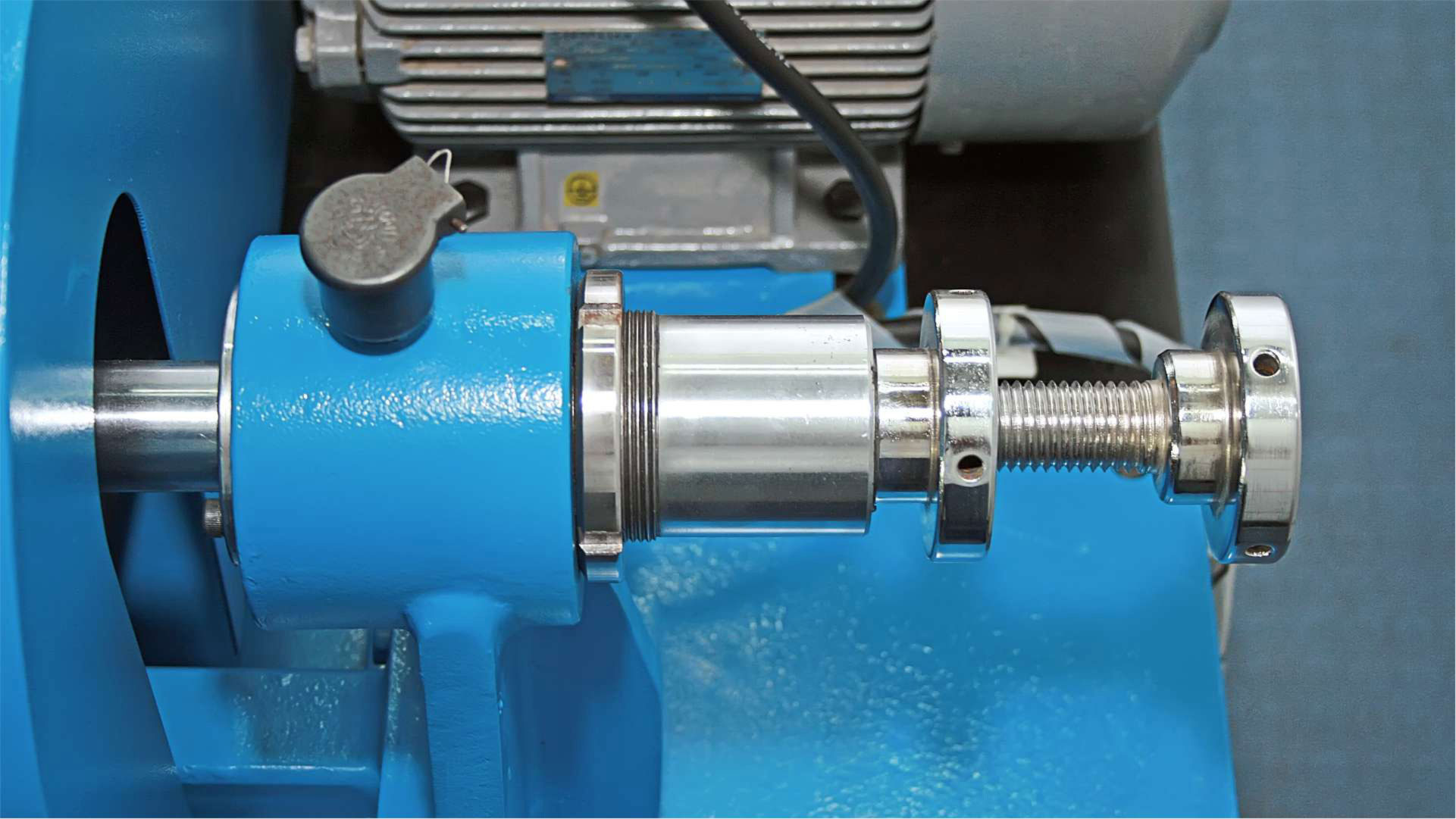

In the grinding media one grinding disc is fixed; the other is spinned by a geared motor, thus exercising a shearing action on the coal/coke sample material to be ground. The gap between the two grinding discs determines the fineness of the material to be ground. By means of a gap adjustment disc to alter the position of the stationary grinding disc the gap width between the two grinding discs can be set repeatably.

Benefits :

- Extremely fast & efficient secondary crushing.

- Rigid & Dust Tight design.

- Feed Size up to 10 mm.

- Out Put Size up to 72 mesh (212 Microns).

- Easy adjustment for setting gap of discs.

- Overload Protection for Motor.

- Easy access to grinding chamber to make easy maintenance and cleaning.

- Combination of insmart disc mill with IJC series of Jaw Crusher allows smooth initial and fine grinding for preparing the necessary pulverized coal samples in quick operation.

Feed Hopper with regulated material flow

Disc gap adjustment